Automatic canning system

Scope of application:

The liquid filling scale accurately packs a large number of bulk liquid materials into various containers, iron barrels or plastic barrels by weight, and is used for automatic quantitative filling of 30L ~ 1200L barrels. It is widely used in chemical, grain, pesticide and other industries related to liquid materials, and is suitable for coatings, paints, inks, adhesives, curing agents, resins, dyes, cleaning agents, engine oils, glycerin, lubricants, edible oils, essence, solvents, additives Food additives, pesticides and other dangerous chemical products.

Intelligent warehouse management system

Detailed introduction:

● standardized, modular, scalable and easy to use.

● compared with traditional warehouse management software, which focuses on Management (mostly on human participation), we focus on real-time automation, intelligence and comprehensive management and control (relying on technical means to avoid human uncertainties).

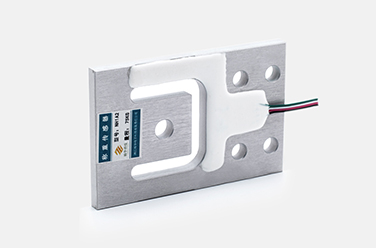

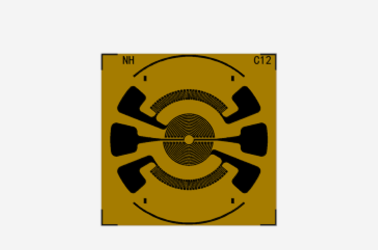

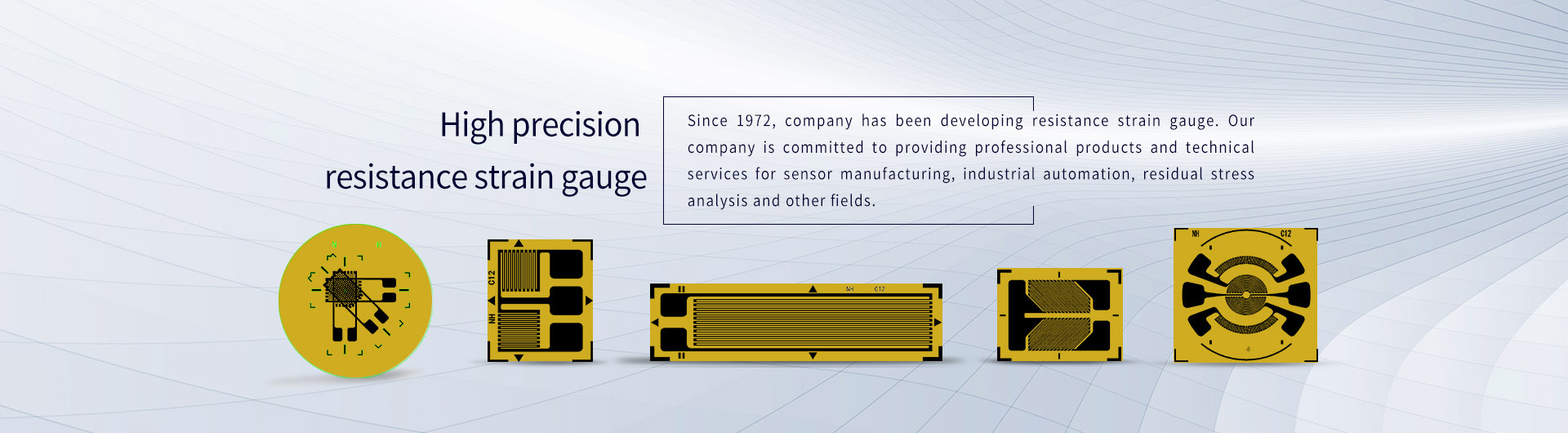

● according to the requirements of customers' different application scenarios and the structural needs of the sales cabinet, various sensor gravity sensing units can be provided. The output signals are divided into analog and digital. The strain gauge, the core element of the sensor, is produced by our company with imported raw materials, with superior performance. The measuring range of the gravity unit can cover 0.1-120kg, and the accuracy can be as high as one in ten thousand. It also provides performance customization for different temperature requirements and creep requirements.

● realize real-time intelligent comprehensive management and control by combining sensing technology and Internet of things technology! Automatic management improves efficiency; Ensure that the system is real-time and accurate Accurate and traceable, reducing human factors; Open up the information island, make the data closed-loop in real time, and make the enterprise production and operation closed-loop in real time.

Intelligent weighing shelf data acquisition system

Detailed introduction:

● the intelligent weighing data acquisition system is composed of high-precision scales, signal converters, and warehouse material management software (which can be connected to ERP system at the same time). The system obtains the material level of each material through weighing technology.

● this system is based on real-time monitoring software and cloud database software to realize real-time monitoring. It can set low to high inventory alarm system, query historical records, connect with ERP in real time, conduct real-time weighing and calibration, and judge whether it is necessary to notify replenishment. The login software realizes real-time access through RFID card identification.

● realize real-time monitoring through the LAN of intelligent shelf system to accurately reflect the current use of components in real time- All item numbers can be set with item number alarms. When the item number is lower than the lower limit or higher than the upper limit, the production material clerk, warehouse manager or external supplier will be automatically notified to replenish in time, so as to reduce staffing and reduce the material cost of the operator's factory.

● for real-time production, the records can be viewed through the local LAN or the Internet version web interface. Reduce personnel costs- Through the real-time monitoring of raw materials, operators can realize the internal zero inventory management of the company through the real-time monitoring of raw materials.

Robot arm

1、 Characteristics

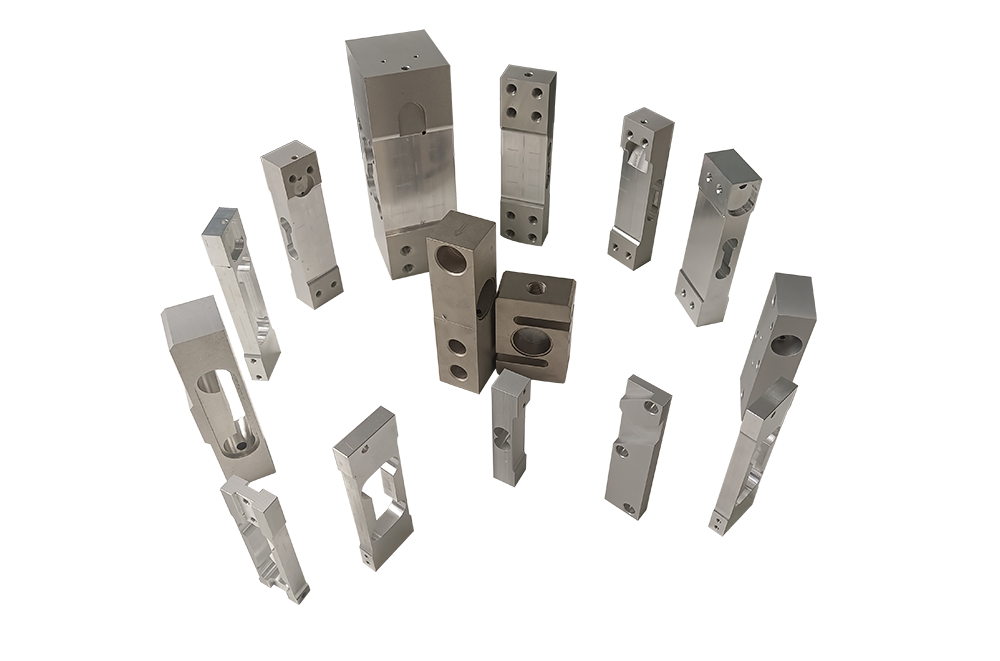

It can measure force and torque components in more than two directions at the same time

Multi axis force sensor adopts structure decoupling technology, algorithm decoupling technology and strict sensor production process. Various output forms, including digital and analog output, are suitable for various complex industrial environments, underwater measurement and other environments. It has been well applied in many regions such as the United States, Germany, Spain, Canada, Japan, Australia, South Korea, Taiwan and the mainland. It has good applications in grinding, polishing, wire drawing, deburring and other fields.

In addition to human simulated multi axis force sensors and multi axis force sensors for robots and automation, there are also ultra-high resolution collision force walls, intelligent data acquisition systems, six axis wheel force sensors, etc. Ultra high resolution collision force wall is used to study the vehicle collision compatibility. Intelligent data acquisition system can measure all kinds of signals, such as full bridge, half bridge, 1/4 bridge, voltage signal, thermocouple, acceleration, etc., and can be widely used in various test occasions. Six axle wheel force sensor can be widely used in vehicle durability test, road spectrum acquisition test, braking test and other occasions.

2、 Market application scope

Automotive Industry: crash testing

Manufacturing: cutting process optimization and tool wear monitoring

Robot: measuring the force of manipulator

Unmanned retail system

Automatic sale of goods: scan the code to open the door - pick up the goods autonomously - close the door to pay;

Intelligent settlement, supporting wechat and Alipay;

Enrich the advertising function;

Regular sales report statistics and analysis;

Real time commodity management;

It can realize the monitoring of equipment operation status;

Remote maintenance.

Smart insole

Pregnant breath