Multi axis inertial sensors have been increasingly favored by the medical application market. Inertial MEMS components with multi axis sensing function have excellent performance in terms of size, power consumption, accuracy and reliability, and can meet the stringent requirements of medical applications. Precision medical instruments such as surgical navigation tools have begun to be introduced in large quantities.

Navigation is related to cars, trucks, planes, ships and people. However, it also began to play an important role in the field of medical technology. Precision surgical instruments and robots must use navigation. The design requirements of surgical navigation tools have broad commonalities with traditional vehicle navigation, but the former also poses some unique challenges, such as being used indoors and unable to obtain the support of global positioning system (GPS), so higher performance is required.

Multi axis MEMS sensors transform medical information

MEMS has become a mature technology that most people encounter every day. It makes cars safer, enhances the usability of mobile phones, and optimizes the performance of tools and sports equipment, thereby improving the level of medical care for patients.

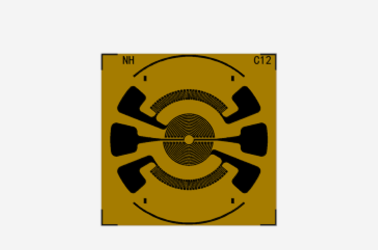

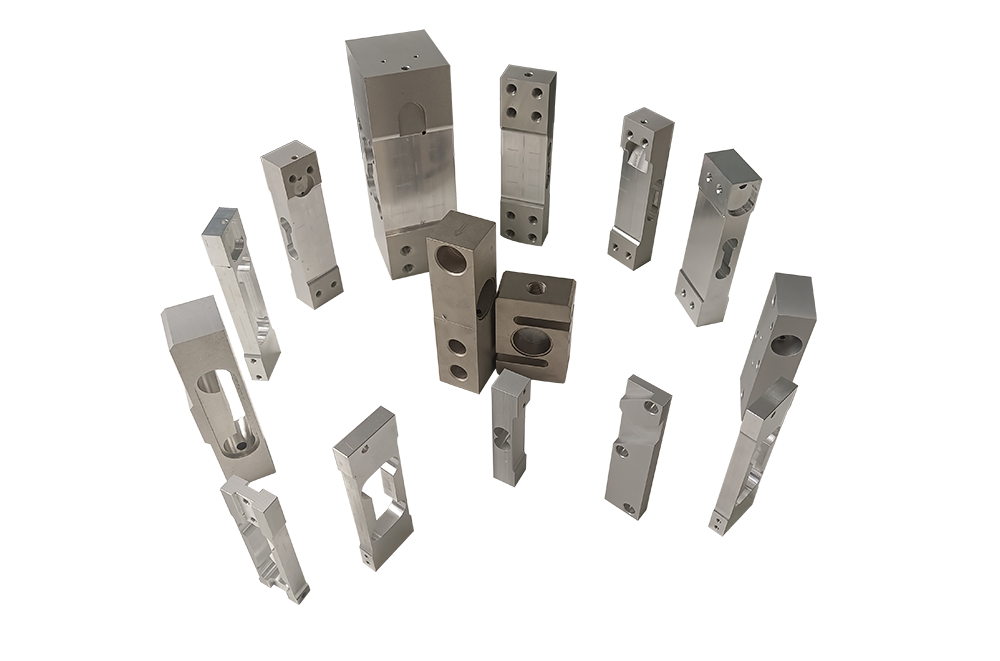

MEMS components used for linear motion detection are usually based on a micromachined polycrystalline silicon surface structure, which is formed on the silicon wafer and suspended on the surface of the wafer through polycrystalline silicon springs to provide resistance to acceleration force. Under acceleration, the deflection of MEMS axis is measured by a differential capacitance, which is composed of an independent fixed plate and a movable quality connecting plate. In this way, the motion makes the differential capacitance unbalanced, causing the amplitude of the sensor output to be proportional to the acceleration.

For example, when a car suddenly decelerates sharply due to a collision, the MEMS axis in the airbag sensor will produce the same movement, causing the capacitance to be unbalanced, and finally generating a signal to trigger the airbag to open. This basic accelerometer structure can be adjusted according to different application performance parameters, and after adding data processing function, it can indicate inclination, speed and even position. Another technically related structure is the gyroscope, which can detect the rotation rate, and the output form is degrees / second.

The ability to detect and measure movement through a very low power consumption micro element is valuable for almost any application involving movement. Table 1 lists basic medical applications by type of movement.

Although simple motion detection is valuable, such as linear motion on an axis, most applications involve multiple types of motion on multiple axes. Capturing this multi-dimensional motion state can not only bring new benefits, but also maintain accuracy when the disturbance outside the axis may affect the single spindle motion measurement.

In order to measure the motion experienced by objects, various types of sensors (such as linear and rotating) must be combined, such as accelerometers, which are sensitive to the earth's gravity and can be used to determine the inclination. In other words, when a MEMS accelerometer is rotated in a ± 1g gravity field (± 90 degrees), it can convert the motion into an angular representation.

However, accelerometers cannot distinguish between static acceleration (gravity) and dynamic acceleration. Therefore, the accelerometer can be combined with the gyroscope, and the linear acceleration and tilt can be distinguished by using the additional data processing ability of the combined element (that is, when the output of the gyroscope shows that the rotation coincides with the obvious tilt recorded by the accelerometer). As the dynamic degree of the system (the number of axes and degrees of freedom of motion) increases, the sensor fusion process will become more complex.

It is also important to understand the impact of the environment on the accuracy of the sensor. One obvious factor is temperature, which can be calibrated. In fact, high-precision sensors can be recalibrated and dynamically compensated by themselves. Another less obvious consideration is the potential vibration. Even a slight vibration will offset the accuracy of the rotation rate sensor. This effect is called linear acceleration effect and vibration correction, and its impact may be serious, depending on the quality of the gyroscope. In this case, sensor fusion can also improve the performance, that is, use the accelerometer to detect the linear acceleration, and then use this information and the calibration information of the linear acceleration sensitivity of the gyroscope to correct.